SPECIAL CONTENTS

What is stainless steel?

Stainless steel is a group of iron based alloys that contain

chromium, a composition that prevents the iron from rusting.

This material was invented

in France and Germany in the early twentieth century and was called “rustless steel” by the

inventor. After that, it was renamed “stainless steel” as a more marketable name.

After

the 18-8 stainless steel was invented, stainless became popular and it’s been widely used in

our everyday life.

Annoyed

with rusted blades?

It is a nuisance to find rust on your cutter blade when you need to use it.

Most cutter knives are installed with carbon steel blades because they are easy to

process and are highly durable. Carbon steel blades are well-balanced cutter blades,

however, this material can get rusted by moisture or if adhered to organic

solvents.

Rustproof oil is applied to our cutter blades, but after they get wet and

deteriorated over time, the blades get rusted.

Rust is invasive and corrosive, and will reduce the performance of your blades.

With

carbon steel blades, you need to constantly check the condition of your blade for

rust.

Cutter knives are used in a variety of places, but some of the places are not in a

favorable environment to be used concerning being rusted.

Rust on cutter blades

will reduce

the performance

of

your work.

Annoyed with rust?

Go stainless

steel !

In general, stainless steel materials are comparatively softer than carbon steel

materials and the difference in hardness affects all the important factors, such as

sharpness, durability and so on. However, through heat-treatment and our expert

polishing processes, our stainless steel blades are favorably comparable with the

sharpness and durability of carbon steel blades.

We currently have “BA-50SS” and “BA5SS” for light-duty (9mm width) and “BL5SS” for

heavy-duty (18mm width) in our lineup.

In Japan, stainless steel blades have been used in a variety of industries, mainly in

the open air, such as in construction, fishing industry, agricultural industry, etc.

Working outdoors, there are many cases in which cutter blades will be exposed to

moisture, for example, rain, sweat and humidity.

In those conditions, stainless steel blade is your best choice.

NT’s SS blades are growing in popularity around the world!

Stainless steel blade is the global choice for various industrial users.

It is especially in the custom-car industry.

For instance, in the U.S. these stainless steel blades have boomed in sales in the

custom-car industry. Since 2010, the American “car-wrapping” has been drawing many

people’s attention around the world.

“Car-wrapping” is when special film is applied to the body of the car and windows. For

the application of window film/tint to car windows, our stainless steel blades have

widely been used.

With technical improvements, the films used for car wrapping are easier to apply and

reapply, leaving less air bubbles.

Car wrapping is also used to change the color of the car and protect the original paint

in its original condition.

There are the competitions where the installers for car wrapping compete against each

other in their techniques.

Out stainless steel blades have been becoming more and more essential for custom-car

craftsmen and have been vastly favored.

Softer stainless steel blades

for scratch-free windows

Point word

Avoid damages with

stainless steel blades

Car interior spaces are becoming more and more comfortable with advanced technology.

But by simply applying window-tinting films, not only would it shield you from the harsh

sun, but it works for anti-scattering and it will enhance the appearance of your car

tremendously.

This popular NT stainless steel blade is perfect for this job and has been used for this

purpose especially in USA. Installers have strict requirements, so there are reasons

that the blades must be stainless steels.

To explain this, let’s start with the hardness of the blades.

Vickers hardness value (HV) is the measure of hardness.

The harder the material is, the larger the figure written before HV.

The hardness of the carbon steel blade is approximately HV770 – 850 which is almost the

same hardness as a car window, therefore if you use it on the window, it could scratch

and damage the window.

On the other hand, the hardness of NT stainless steel blade is approximately HV700 –

750. Our stainless steel blades are softer than our carbon steel blades, making the

possibility of scratching the car windows far less.

When you apply the film, you need to stretch it along the curved surface of the car

window, so often times the film is precut larger than the actual size you need.

This is where the stainless steel blade is used to cut off the extra film.

To perfectly cover the window with the film, you should cut the film on the car window,

in which case the blade touches the surface of the window.

With carbon steel blade, the blade will most likely scratch the surface of car windows

when cutting off the extra film.

The scratches left behind could potentially become larger with just the natural

vibration caused by wind while driving and with one hit from a small stone on the road,

the window may possibly break.

The blades that lessen the possibility of scratching car window and is highly

resistant to rust

In addition, when applying window tint, a special liquid containing surfactant is

used to remove grease.

Surfactant can damage and cause rust to form on carbon steel blades. For these

reasons, carbon steel blades are clearly not suitable for the application of window

tint.

The smart choice for the application of window tint is without a doubt, the

rust-resistant, softer stainless steel blades. NT stainless steel blades will

improve your operations, efficiency and quality of work!

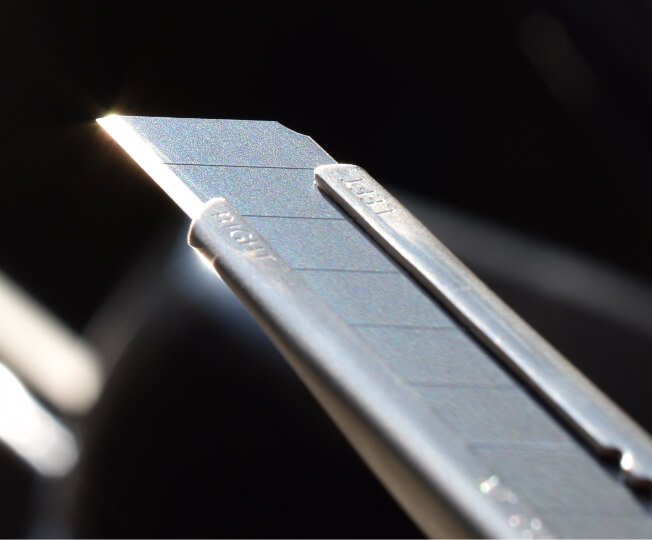

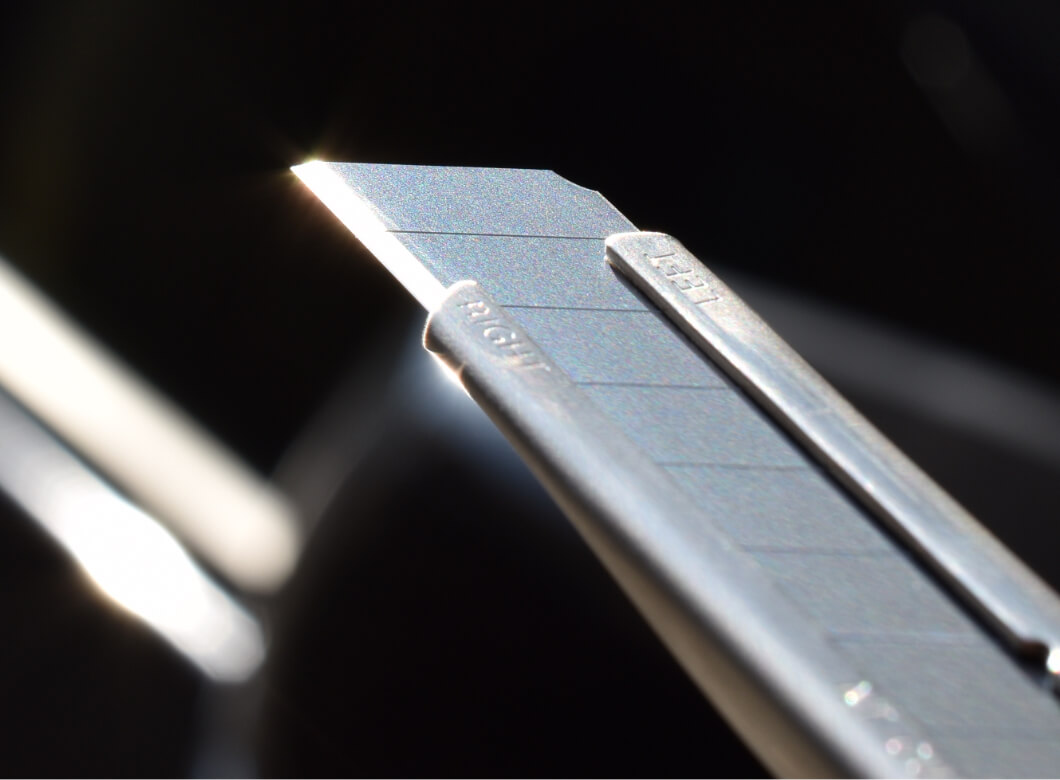

First NT cutter

with both Stainless Steel

holder and blade!

In January of 2020,

we released a cutter specifically

for the window film

installers.

Window film cutter, “STL-ONE”

The slim holder is perfect for the fine detailing and it’s made of high quality stainless

steel “18-8” which is highly resistant to rust and is durable.

It’s symmetrically designed for left and right handed users. It is the same holder we use

for “A-1P” and “AD-2P”.

At first glance, “STL-ONE” is different only in color from “A-1P” and “AD-2P”, however this

model has 2 special features which “A-1P” and “AD-2P” do not have.

*The “STL-ONE” is sold as A-1P in the United States and is widely known under the nickname

of “Red Dot” ,differently colored from STL-ONE.

Unlimited possibilities

One difference is the blade, which is the key for cutter knives.

The “STL-ONE” cutter comes already equipped with a high quality stainless steel

blade (BA-50SS).

Stainless steel blade is required for window tinting film application since it’s

highly resistant to rust and comparatively softer than a car window.

In the operation where there is a concern over the hardness and rust of a blade,

NT “STL-ONE” is a great option.

High resistance to organic solvent

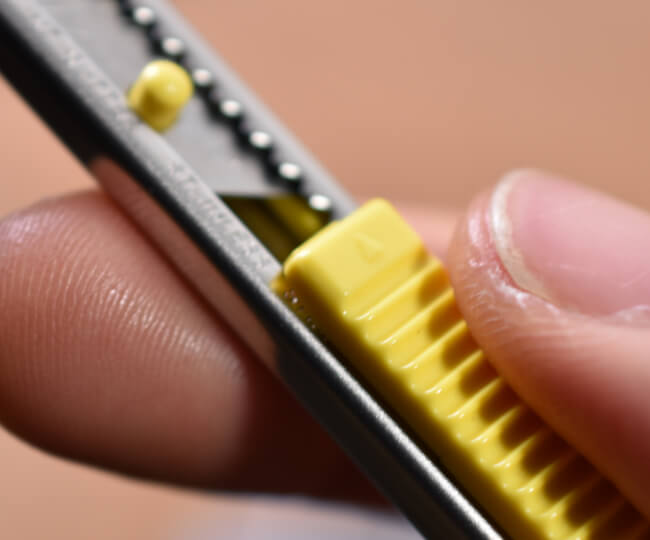

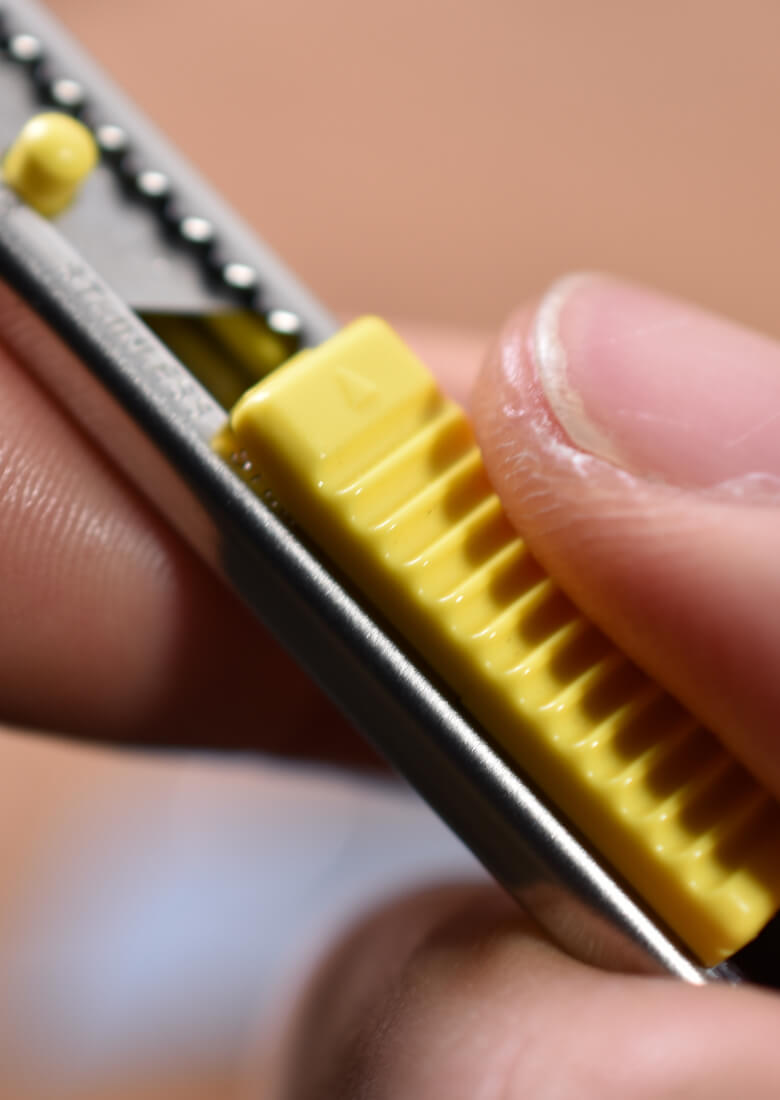

Another feature of the “STL-ONE” is the plastic parts in bright yellow which

will stand out in any workplace.

These plastic parts are made of high quality resin, which have excellent

resistant to organic solvent and machine oil.

In most workplaces for customizing cars, there are many organic solvents around,

such as paint, thinner glue, etc.

Standard plastic has less tolerance for organic solvent and can ruin the smooth

movement of the cutter knives. To solve this problem, special resin is equipped

in the “STL-ONE”, to improve the durability against organic solvents.

With this improvement, not only is it difficult for the plastic parts to melt,

but it makes it possible for you to clean your tool with organic solvents.

“STL-ONE” is the clear choice to other standard cutter knives for these

reasons.

“STL-ONE” follows the great features of NT “Pro series” additionally with the

capability to be used when water and organic solvents are involved.

The utility knife with

infinite use

It is obvious that cutter knives must cut materials smoothly and effortlessly.

However, to meet the demands of consumer needs, additional features are necessary to

expand the possibilities of cutter knives. “STL-ONE” was introduced with this in

mind.

We believe that cutter knives should be freely used and the users should decide how and

what to use them for.

Even though we ideally named the “STL-ONE” as the “Window film

cutter” to spotlight the specific use, it is not only for the application of

window-tinting films.

Stainless steel blade is highly resistant to rust.

High quality resin parts have excellent resistance to organic solvents.

Holder is made of high quality stainless steel (18-8) which is highly resistant to

rust and durable.

“STL-ONE” is an essential tool for a wide range of uses.

How will you use your “STL-ONE”?

We believe that every user will find

that the “STL-ONE”

will be useful in various tasks by taking advantage

of its special features.